Technical Information

Applications

Kemlon manufactures a complete line of high pressure high temperature electrical feedthru connectors for use in severe environments. These connectors are widely used in such demanding services as down hole geophysical exploration where heat, salt water, hydrogen sulfide, and other corrosive mediums are present. Other applications are for marine, aerospace, nuclear, and medical where the highest quality product is required.

Connector System

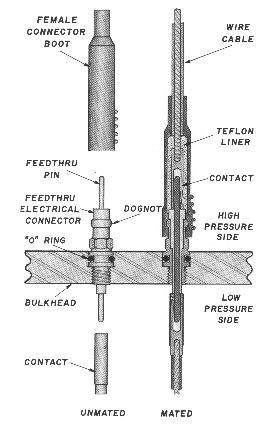

The single pin connector system consists of a feedthru connector mounted in a bulkhead and a female connector (commonly referred to as a boot) which plugs onto the male connector. Inside the boot is a contact which grips the metal pin on the male bulkhead connector. Boot and contact are sold together as a set. The boot is either bonded to the wire cable or slips onto the wire tightly and makes a seal on the cable. The boot fits tightly on the dognot of the connector and makes a seal there also. Inside the boot current passes through the wire, through the contact, and finally through the connector pin. A seal between the connector and the bulkhead is most commonly made with a rubber "O" ring, but Can be made with a pipe thread or a metal ring. Kemlon's connector system is covered by one or more of the following patents: 4,077,261 3,793,608 and 3,898,731.

Duo-Seel

Kemlon's trade name Duo-Seel is used with our booted feedthru connectors. It means two seals, one being the boot and the other being the bond of the insulator to the body/pin. It is not intended to mean dual pressure direction, which is a special design requirement.

Standard Configurations

Kemlon manufactures three standard sizes of single pin feedthru connectors. These are shown in Figure 2. The smallest is K-16, and it is used where only the smallest connector will fit. The K-25 is the most commonly used size, and therefore more versions in this series are available from stock. The K-30 is the largest, and it is ordinarily used for high current applications.

Pin Terminations

Straight pin terminations are standard on Kemlon Duo-Seel connectors on the low pressure side. However, other pin terminations which are listed below are available upon request. Eyelets lengthen the pin approximately 0.03 inches.

Construction

Kemlon manufactures five different versions of the single pin feedthru connector. Each has certain advantages and disadvantages over other versions. The purchaser should choose the model that is best suited for his application.

| Insulation | Polyether | Glass Sealed Plolyether | Glass Bonded Ceramic | Ceramic |

|---|---|---|---|---|

| Body | 304 S.S (316 S.S*) | 304 S.S (Inconel*) | 304 S.S (Inconel*) | Inconel |

| Pin | Beryllium Copper | Nickel / Iron Alloy | Nickel / Iron Alloy | Kovar |

| *Inconel or 316 S.S. are available by special request. In some models the pressure rating can be significantly increased by specifying Inconel for the body material. Consult Kemlon for the application of Inconel to a specific part | ||||

Polyether

Kemlon's polyether model is similar to the epoxy model but utilizes an aromatic polyether pressure molded pin bonded in place. This model has good high temperature and electrical properties compared to the epoxy model. It is low cost, but not recommended for unbooted service. A boot is required for sealing.

Glass Sealed with Polyether

This model consists of a glass sealed feedthru connector with polyether insulators bonded on each end. The polyether insulators are bonded in place in a second operation. The back insulator may be polyether or teflon in some cases. The model has good high temperature and electrical properties. It is recommended that a boot be used, but this model may be used unbooted in an oil system.

Glass Bonded Ceramic

Kemlon's glass bonded ceramic connector has a pin hermetically sealed to the body with glass. The ceramic insulators are also bonded in place with glass using one or more of Kemlon's patented processes. This model can operate at very high temperatures and has been used in geothermal applications. It is recommended that a boot be used, but this model may be used unbooted in an oil system.

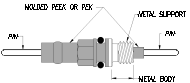

Kemthread™

The Kemthread is an aromatic polyether ketone plastic (PEEK or PEK) insulated feedthru that utilizes a high strength metal support that is designed to inhibit creep and operate at high temperatures and pressures. The connector seals to vessel with a single rubber o-ring located in its plastic body. The plastic is molded to the conductor to provide a high-pressure hermetic seal. The thermoplastic construction provides for longer arc paths, is more tolerant of bending, and will not ordinarily crack. The Kemthread is currently available in the BMA configuration with various materials of construction and can be supplied in most other configurations except the BM, PT, RP, and dual pressure feedthrus. It is recommended that a boot be used, but this model may be used unbooted in an oil environment.

Ceramic

Kemlon's all ceramic model consists of a pin bonded to a ceramic insulator, which is bonded to the metal body. In this version the ceramic insulation is continuous along the pin. This model is a recent development and is only available in limited part numbers presently.

Current Capacity

Current carrying capacities of Kemlon connectors are listed by the specific part number in this catalog. In the case of the male bulkhead connectors, the current capacity listed is the maximum recommended operating current based on a temperature rise of 500F. The male plastic connectors generally have a higher current capacity because their pins are constructed of beryllium copper. This is a better conductor than the nickel-iron or kovar alloys used in the glass-sealed versions. In the case of the female boots and molded cables, the current capacity is generally limited by the capacity of the wire or cable rather than the spring contact. Currents 50% greater than those listed for male and female connectors are possible for very short periods of time (three seconds maximum) since there is not enough time for heat to damage the insulation.

Voltage

The Kemlon connector system has been designed to operate at 500 V.D.C. while at maximum temperature and pressure in a conductive water environment. If the application is less severe than these conditions it is likely that higher voltage ratings are possible. The male connector voltage ratings are listed in this catalog for ambient conditions, which is the ideal condition. If operating voltages are greater than 500 volts, tests should be run to determine the suitability of the connector system for the specific application. Much higher operating voltages can be achieved with Kemlon's models K-28 BMHV and K-28 BMAHV. These models have been designed to operate at 4500 V.D.C. while at maximum conditions. These connectors require special boots which correspond to the elongated configuration.

Insulation Resistance

The insulation resistance of a Kemlon male bulkhead connector is a function of temperature. As the temperature is increased the resistance falls. Values in Ohms versus temperature in degrees Centigrade are plotted in Figure 3. These values were obtained from connectors heated in a dry oven and measured at 500 V.D.C. As shown, the epoxy model has the lowest readings; the polyether, glass sealed polyether, and glass bonded ceramic have medium readings, and the all ceramic model has the highest reading. The insulation resistance of female boots and molded cables in a conductive water environment is determined by the type of rubber compound that is chosen, unless the boot is teflon lined. The insulating qualities of rubber diminish with increased temperature and with exposure to hostile environments. A plot of resistance at 500 V.D.C. for boots made from various rubber compounds versus temperature in degrees Centigrade in a dry oven is shown in Figure 4. If a teflon lined boot is selected, the teflon insulates the electrical contact and improves the electrical readings of the boots.

Helium Leakage

Kemlon glass sealed with polyether, glass bonded ceramic, and all ceramic connector versions are fabricated to meet or exceed a helium leak test of 10^-8 cc/sec. Representative samples are inspected using a mass spectrometer helium leak detector to insure product integrity. In extreme cases 100% batch inspection can be performed at an additional charge. The epoxy and polyether plastic versions are not designed to meet this specification.

Plating

All male bulkhead connector pins and female contacts are gold plated for maximum electrical contact. Gold plating is to Kemlon's specification of 10 micro inches unless otherwise requested.

Quality Control

Kemlon maintains a quality control program with complete manufacturing documentation and tractability. The program is in accordance with and exceeds MIL 9858-A for military systems requirements and is designed to achieve very reliable products. A written schedule for calibrating gages, measuring and test equipment is strictly followed in accordance with MIL 45562. We routinely perform mass spectrometer leak testing, high potential spark testing, microscopic sectioning, high pressure (25,000 PSI) pressure testing and other inspection/testing procedures to maintain high quality assurance at very high levels.