Technical Information

Kemlon Products and Affiliates have been manufacturing pressure proof electrical connectors for the Petroleum Industry since 1950. Today Kemlon manufactures a complete line of pressure proof connectors for various hostile environments including underwater, subsurface oil well, and high temperature steam. These components are supplied worldwide to compa nies for exploration and production of oil, gas, and steam.

Kemlon Products is a well established broad base manufacturing operation. Kemlon manufactures all metal compo nents in house utilizing modern computer controlled equip ment. Further, all plastic and rubber molding are done in house including rubber mixing and mold making. The company has developed a substantial number of proprietary rubber com pounds for use in connector applications. Kemlon maintains a staff of ten graduate engineers with an average experience level of 15 years.

The SL-5000 series connectors found in this catalog offer a complete range of power ratings for the new 5000 volt stan dard. These connectors offer up to 25% more power handling capacity over other designs in the market place of the same overall diameter. Kemlon can provide these connectors to fit most wellhead configurations. In some cases mandrel dimen sions may be adjusted for a specific application. These connectors are constructed of the most advanced insulating mate rials and contain many improvements over other designs.

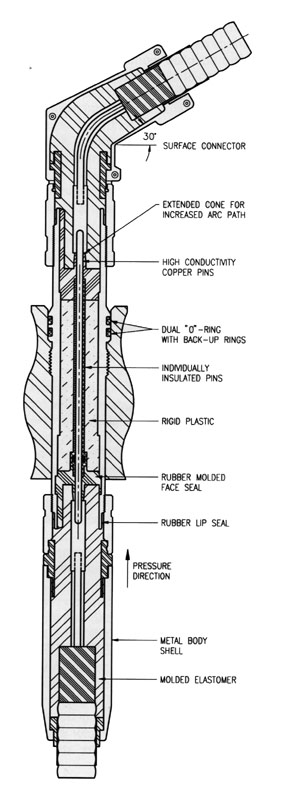

The connector system typically consists of a mandrel mounted into a wellhead or tubing hanger. A surface connector plugs onto the air side and a lower connector plugs onto the pressure side. The lower connector can be either a molded pig tail or a field attachable connector. A molded pigtail is made by vulcanizing the lower connector directly to a length of cable. This pigtail would then be spliced to the pump cable. The lower connector can also be supplied as a field attachable connector, which is designed to be attached directly to the pump cable thereby avoiding a splice. Field attachable connectors can be molded from a variety of materials, since the cable is not pre sent during the curing but added later. The surface connector is typically a molded pigtail that can be supplied as an explosion proof or a nonexplosion proof model. The explosion proof surface connector has more threads for mating and unmating safety and therefore the coupling nut is longer. The SL-5000 connector mandrels are the same for explosion proof service or nonexplosion proof service. Less threads are engaged on the mandrel when a nonexplosion proof surface connector is used, but the same mandrel is used for both services. The system is explosion proof when an explosion proof surface connector is used with the standard mandrel. The surface connector is also available as a field attachable connector, but in the straight shell configuration only.

The Kemlon SL-5000 series system has many advanced features over other systems. One feature is the extended insu lating cone which is molded onto the mandrel pin. This length ens the arc path between pins, thereby reducing the chance of electrical shorting pin to pin. The explosion-proof surface con nector is designed so that the coupling nut has ample thread engagement before the electrical contacts would mate or demate in case of an accidental connection with the power switched on. When the lower and surface connectors are mated to the mandrel, a rubber lip seal forms between the plugs and mandrel, which seals out any water or hydrocarbon liquids and gases. This greatly improves the life of the system over those that do not have an interlocking seal. In addition the SL-5000 series connectors have a molded interface which seals the face of the mandrel, thereby preventing moisture from migrating into the insulating material of the mandrel. The pins are dually insulated virtually their entire length with a highly insulating elastomer and a rigid plastic dielectric. The pins and contacts are constructed from high conductivity cop per and are gold plated for higher corrosion resistance and lower contact resistance. The rigid plastic insulation mechani cally supports the pins in the mandrel as well as bonding the pins to the metal shell. The metal shells are normally con structed from 4140 steel per NACE MR-01-75 and cadmium plated. They can be supplied from other alloys upon request. The mandrel shells are designed with dual "0" ring seals and back-up rings. They are normally furnished with back-up rings and 90 durometer fluoroelastomer "0" rings. The explosion proof surface connector is housed in a monel shell to protect and support the molded plug. The lower connector is encased in a metal sleeve for mechanical support and to reduce the gas expo sure. The contacts are dually insulated with two layers of molded elastomer to ensure electrical isolation. Optional elastomers are available to satisfy the most demanding applica tions.

Mateability

The SL-5000 surface connectors are mateable to the surface end of the feedthru mandrels and other surface connectors found in this catalog. The surface connectors are not mateable to the lower connectors or the lower end of the man drel connectors. The lower connectors are mateable only to the lower end of the feedthru mandrel.

Rubber Materials

Kemlon compounds a variety of rubber materials in house. These materials are carefully weighed and then mixed using a Banbury and Calendar mill. Each batch is given a batch number and is tested by our quality control department to ensure that it meets our specifications. Extensive testing has gone into the development of many of these formulations so that specific applications could be satisfied. See chart below.

| RUBBER COMPOUND | COMPOUND CLASSIFICATION | SUGGESTED SERVICE TEMPERATURE-F | OIL RESISTANCE | RECOMMENDED USES |

|---|---|---|---|---|

| KN-01 | Neoprene® | -65 to 250 | Fair | Surface Connector - Standard Connector Mandrel - standard |

| KN-02 | Nitrile | -25 to 240 | Good | Lower Connector - pigtail option Connector Mandrel - optional |

| KN-79 | EPDM | -55 to 300 | Poor | Pin insulation where isolated from exposure to hydrocarbons |

| KN-82 | Ethylene / Acrylic | -55 to 300 | Good | Lower Connector - optional Connector Mandrel - optional |

| KN-34 | Fluorocarbon | -20 to 400 | Excellent | Connector Mandrel - optional Field Attachable - optional |

| KN-84 | Fluorocarbon | -20 to 400 | Excellent | Connector Mandrel - optional Field Attachable - optional |

Rubber material options are available throughout this catalog, because no one material is best suited for all applications. Nitrile rubber has better resistance to gas and hydrocarbons than Neoprene, but is not as flexible at cold temperatures. Flurocarbon rubber has excellent resistance to hydrocarbons, but is limited in bonding applica tions where the second material can withstand the curing temperatures. Consult the factory for material choices and availability.

Current Capacity

| WIRE SIZE AWG | AREA SQ.IN. | CURRENT AMP |

|---|---|---|

| 6 | 0.021 | 95 |

| 4 | 0.033 | 125 |

| 2 | 0.052 | 170 |

| 1 | 0.065 | 210 |

| PIN DIA INCHES | AREA SQ. IN | CURRENT AMPACITY |

|---|---|---|

| .203 | .032 | 75 |

| 0.234 | 0.043 | 100 |

| 0.250 | 0.049 | 125 |

| 0.281 | 0.062 | 150 |

Quality Control

Kemlon maintains a quality control program with complete manufacturing documentation and traceability. Kemlon's program exceeds the system requirements of Mil-l-45208. In addition a written schedule for calibrating gauges, measuring, and test equipment is strictly followed in accordance with Mil-C-45662. Kemlon's inspectione partment utilizes modern equipment such as metal analyzer, tensile tester, Coordinate measuring machine, beta backscatter gold plating testers, optical comparators, various electrical and mechanical instruments, and hydrostatic pressure testing. All SL-5000 connectors are 100% electric tested for insulation resistance and withstanding voltage. All SL-5000 connector mandrels are 100% pressure tested prior to shipment